Type 316 stainless steel is not just harder to machine but requires special tools to cut. Think car fenders and stainless steel serving trays. That is also why it is used on surfaces that are visible to the public. That is one reason why it comes in so many different finishes. Not only is grade 304 steel easier to machine but it is easier to clean.

Type 304 is more machinable than 316 stainless steel. However, its relative weakness means it isn’t used as often as grade 304 stainless steel. That makes grade 303 steel the first choice for fittings, gears, and fasteners where tight tolerances are a must.

#18 8 STAINLESS STEEL VS 316 SERIES#

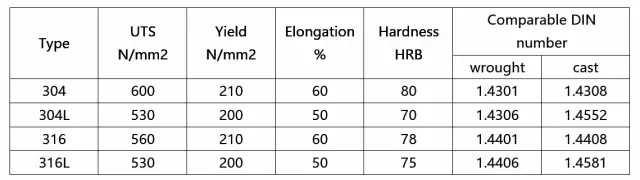

Type 303 stainless steel is probably the easiest 300 series to machine. However, the 304 and 316 grades of stainless steel do differ in their machinability. That includes grade 304 and 316 stainless steel. The 400 series of stainless steel is easier to machine than the 300 series of stainless steel. What grade of stainless steel is best for machining?Īustenitic stainless steels are generally considered difficult to machine. Grade 304 stainless steel is rarely marked in this way. Items made of 316 stainless stee l may be marked with a 6 inside of a circle. A material test report is necessary to know the difference if they aren’t specially marked. Note that you can’t see the difference between the two grades of stainless steel. This is why 304 stainless steel is considered ideal for food processing equipment and hot water systems. It can withstand corrosion from most oxidizing acids, making it easy to sanitize. It is also less heat sensitive than even grade 302 steel. In fact, 304 stainless steel is the most widely used austenitic stainless steel in the world. That’s why it is used in wheel covers, electrical enclosures, and general steel pipes. While grade 304 stainless steel is fine for most other applications, type 304 stainless steel is cheaper and easier to fabricate. Grade 304 stainless steel is weak compared to 316. Grade 316 stainless steel can resist temperatures up to 1600 degrees Fahrenheit.

For example, it will resist fatty acids at high temperatures as well as sulfuric acid. Type 316 stainless steel is more chemically resistant, as well. That makes it the obvious choice for a floating oil rig and oil refinery piping. The presence of molybdenum is why 316 stainless steel is called marine grade stainless steel. Grade 316 steel also contains trace amounts of silicon, carbon, and manganese. It rivals the corrosion resistance of titanium and high nickel alloys. That element is added to help it resist corrosion by chlorides such as those found in seawater or de-icing salts. This means one of the biggest differences between 304 and 316 stainless steel is the presence of molybdenum in 316 type 304 never contains it. Grade 316 stainless steel or A4 stainless steel has around 16 percent chromium, 10 percent nickel, and 2 to 3 percent molybdenum. The 304 grade of stainless steel, also called A2 stainless steel, contains 18 to 20 percent chromium and 8 to 10 percent nickel. 316 stainless steel? What is the difference between 304 and 316 stainless steel? However, you might ask, what is the difference between 304 vs. Let’s learn more about the most commonly used grades of stainless steel before discussing the machining of each grade of stainless steel.

They vary in formability, strength, and machinability. However, there are many grades of stainless stee l. Stainless steel is widely used due to its corrosion resistance.

0 kommentar(er)

0 kommentar(er)